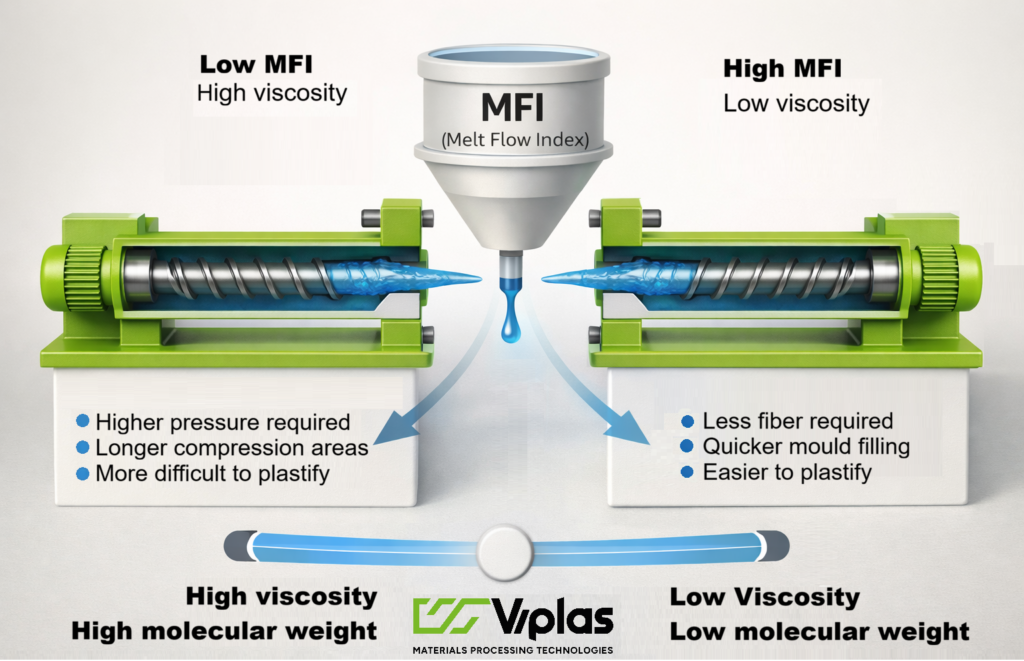

Melt Flow Index (MFI): meaning and role.

The Melt Flow Index (MFI), or Melt Flow Rate (MFR), measures how much molten polymer flows through a standard nozzle in 10 minutes under set conditions (g/10 min). It is a key rheological parameter for thermoplastics, inversely related to melt viscosity and indicative of molecular weight: low MFI means higher viscosity and molecular weight, while high MFI means lower viscosity and molecular weight.

The ISO9001 certification, another milestone in Viplas development.

Since 2001, we have been producing plasticizing screws and barrels for domestic and international customers, primarily serving major manufacturers of machinery and systems for plastic extrusion, molding, blow molding, and recycling. Those of you who already know us or who follow us more actively have witnessed how, since 2023, Viplas has embarked on a decisive […]

TPE-S: is it rubber or is it plastic?

A styrenic thermoplastic elastomer, or TPE-S, is a material intermediate between rubber and plastic—it has characteristics of both. Let’s look at them in detail: 🔹 Structure It is composed of styrene blocks (rigid) and elastomeric blocks (rubbery), typically butadiene or isoprene (e.g., SBS, SEBS). 🔹 Behavior • At room temperature → it behaves like rubber […]

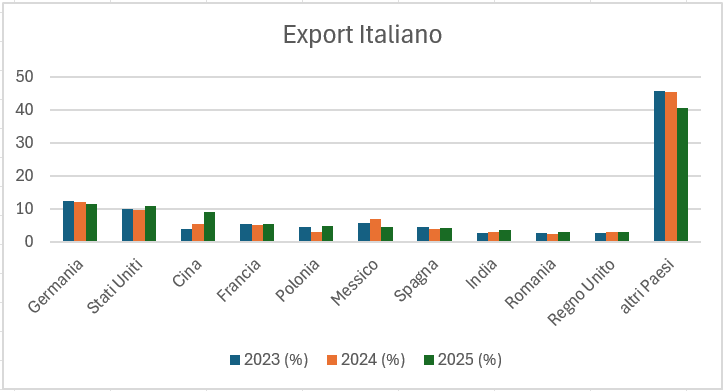

News from the markets

China continues to grow rapidly (both as a destination market and as a machinery manufacturer and exporter), Germany is stagnant, and the United States has been stagnant for three years (waiting to see the effects of tariffs). Reading the latest manufacturer news from the AMP Amaplast website, the following conclusions can be drawn: Europe:Most dynamic […]

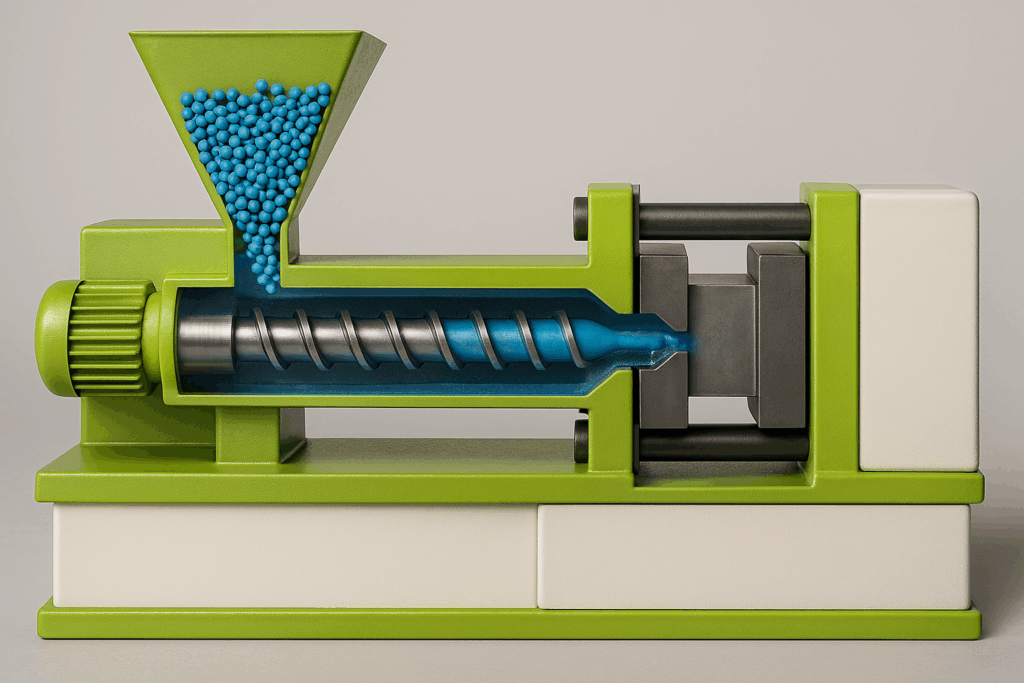

How to choose the right mixer in a plasticizing unit: a balance between materials, objectives, and design.

The choice of mixer in an extrusion plasticizing unit is never a matter of chance: behind each configuration lies a rationale that combines the characteristics of the raw material, mixing objectives, and system limitations. Simply put, it’s a balance between what we want to achieve and what the machine can handle. A plasticizing unit in […]

Hot Summer! The effects of heat and UV on plastic products

Exposure to sunlight, especially under full summer sun with temperatures around 100°F, can significantly affect plastic products, particularly those made from thermoplastic polymers. These materials tend to degrade over time due to UV radiation, heat, and oxidative effects from the environment. Here’s an overview of the main negative effects and potential damage: 🔥 1. UV […]

Working with PVC: 4 key Requirements for Screws and Plasticizing Barrels

When working with PVC, whether in injection molding or extrusion, screws and plasticizing barrels must have specific features to prevent material degradation and ensure efficient processing. Compared to other polymers, PVC requires special considerations due to its thermal sensitivity and tendency to release hydrochloric acid (HCl) during processing. Special requirements for screws and barrels used […]

The effects of additives on the productivity and efficiency of the plasticizing unit

Various types of additives are used in extrusion processes. The most important additive groups used include: Internal and external lubricants, nucleating agents, viscosity modifiers, heat stabilizers and antioxidants, impact modifiers, dyes and pigments, fillers, etc. The selection depends on the type of plastic used, the desired properties of the final product, and the specifications of […]

Preview 2025

The start of a new year is the right time to analyze what 2024 has been and what we intend to achieve in the new year. The past year has been an important one, during 2024 the prices of polymers used in the molding and extrusion of plastic materials have shown downward variations, influenced by […]

Viplas at GREENPLAST 2025, the fair of the circular future of plastic and rubber

GREENPLAST is the international exhibition-conference dedicated to materials, technologies and transformation processes of plastic and rubber, with a focus on sustainability, recovery, recycling and energy efficiency – which will take place from 27 to 30 May 2025 at Fiera Milano (Rho). The fair will present the most advanced solutions aimed at the circular economy and […]