The choice of mixer in an extrusion plasticizing unit is never a matter of chance: behind each configuration lies a rationale that combines the characteristics of the raw material, mixing objectives, and system limitations. Simply put, it’s a balance between what we want to achieve and what the machine can handle.

A plasticizing unit in a plastic extrusion plant is a critical component responsible for melting, homogenizing, and pressurizing the polymer before it is extruded through the die. The choice of mixing element, also known as a “mixer” or “mixing element,” within the extrusion screw is crucial to process efficiency and final product quality.

The relationship between screw and mixer design, its effects, mixing efficiency, and the type of materials being mixed is complex. Let’s analyze them in detail:

Factors influencing the choice of mixing element type:

1. Polymer Type:

- Amorphous polymers (e.g., PS, PVC, PMMA): These tend to have a viscosity that decreases rapidly with increasing temperature and shear. They may require mixers that generate good dispersive shear without excessive heating.

- Semi-crystalline polymers (e.g., PE, PP, PA): They have a more complex melting phase and a viscosity that may be less sensitive to shear. They may benefit from mixers that promote both dispersive and distributive mixing.

- Elastomers and High-Viscosity Polymers: These require mixers that can generate high shear forces to break up agglomerates and evenly distribute additives.

2. Type and Percentage of Additives:

- Pigments and Fillers (especially those with high filler content): These require strong dispersive mixing to break up agglomerates and distribute them evenly throughout the polymer. Mixers with high shear are often preferred.

- Low-Percentage Additives (e.g., stabilizers, slip agents): They require good distributive mixing to ensure homogeneity at the molecular or micrometer scale.

- Fibers (glass, carbon): Mixing must be carefully balanced to avoid excessive fiber breakage, which would compromise mechanical properties. Mixers with controlled shear and smoother flow paths may be preferred.

- Liquid Additives: Their incorporation requires mixing that rapidly disperses them in the molten polymer.

3. Mixing Objectives:

- Distributive Mixing: The goal is to rearrange the different components of the material so that they are uniformly distributed throughout the space. It is important for color homogeneity and the dispersion of liquid additives or low percentages of solids.

- Dispersive Mixing: The goal is to reduce the size of agglomerates or solid particles and disperse them uniformly in the molten polymer. It is crucial for dispersing pigments, fillers, and fibers, and breaking down polymer gels or nodules.

4. Production Requirements:

- Output: More complex mixers can offer better mixing for the same screw length, allowing for a higher output or shorter screws.

- Temperature Control: Some mixers can generate more heat than others due to high shear. This must be managed to avoid polymer degradation.

- Flexibility: Some mixers are more versatile and can handle a wider range of materials or operating conditions.

Common Mixer Types and Their Characteristics:

Each mixer type is a compromise between dispersive and distributive mixing, heat generation, pressure drop, and production costs.

1. Maddock-Style Mixer (or Maddock/Cavity Transfer Mixer – CTM):

- Design: Features a series of cavities and ribs that force the polymer through narrow channels and undergo repeated shearing and flow doubling.

- Effects and Efficiency: Excellent for distributive mixing due to flow doubling and plate rearrangement. It also generates good dispersive mixing due to high shear rates in narrow zones. It is very effective at breaking gels and dispersing pigments.

- Design Parameters: The number of cavities, their depth, and the shape of the ribs influence mixing efficiency and heat generation.

- Material Type: Versatile. Particularly effective for amorphous polymers and for dispersing difficult pigments or fillers.

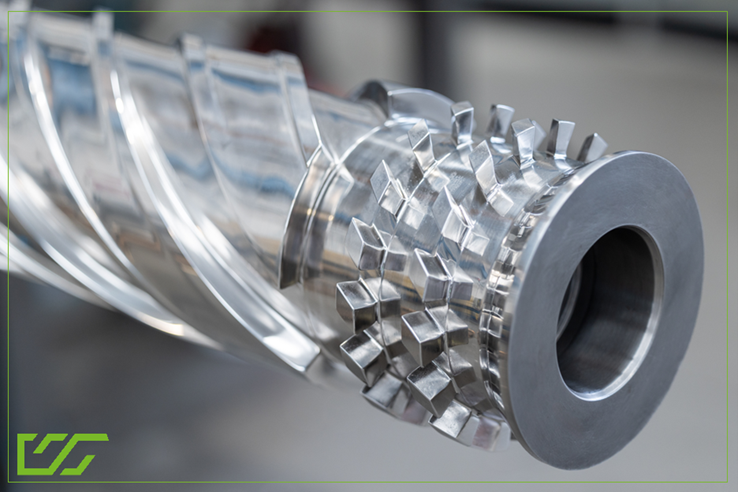

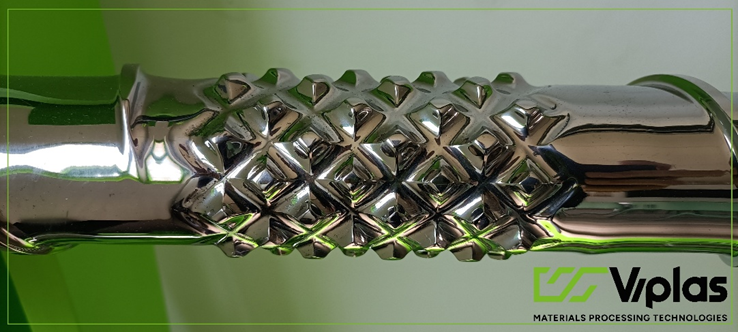

2. Pineapple-Style Mixer (or Pin Mixer):

- Design: Characterized by a series of pins protruding from the root of the screw and/or the wall of the cylinder. These pins interrupt the laminar flow of the polymer.

- Effects and Effectiveness: Primarily for distributive mixing. The pins interrupt the laminar flow by dividing and recombining it, improving homogenization. The shear generated is moderate.

- Design Parameters: The number, arrangement (staggered or in-line), and geometry of the pins influence the effectiveness and pressure drop.

- Material Type: Useful for shear-sensitive polymers and for applications that primarily require good homogenization. Less effective for breaking up hard agglomerates.

3. Barrier Flight Mixers:

- Design: They use an additional thread (barrier) that separates the main screw channel into two subchannels. This forces the polymer to flow over the barrier thread, creating a shearing action.

- Effects and Efficiency: They offer a combination of dispersive and distributive mixing. The passage of the polymer over the barrier generates high shear (dispersive), while the separation and recombination of the flows contributes to distributive mixing. They are also effective at separating unmelted particles (solids) from the melt.

- Design Parameters: The height and thickness of the barrier thread, the length of the barrier section, and the number of threads influence effectiveness.

- Material Type: Very versatile, often used with semi-crystalline polymers or when good melting and homogenization is required. Examples include Maillefer, Dray, and Dulmage barrier screws.

4. Maillefer-Style Mixer (specific type of barrier screw):

- Design: This is one of the most common barrier screw configurations. It has a gradually narrowing main channel and a “melt” channel separated from the barrier thread, which widens. The solid polymer is gradually melted and forced into the melt channel.

- Effects and Efficiency: Excellent for melting and dispersive and distributive mixing. The design optimizes heat transfer and melting, reducing residence time and improving efficiency.

- Design Parameters: Channel aspect ratio, barrier thread depth, and section length.

- Material Type: Excellent for semi-crystalline polymers such as PE and PP, where controlled melting is crucial.

5. Dispersive Mixers with High Shear Sections (e.g., Distributive Mixers, Maddock Sections, Kneading Blocks in Twin-Screw Extruders):

- Design: Often incorporated as discrete screw sections. They feature complex geometries with narrow channels and forced passages that induce high shear rates.

- Effects and Efficacy: Primarily focused on dispersive mixing. They break agglomerates of pigments, fillers, and gels through the application of high shear forces. In single-screw extruders, the dispersive effect is more limited than in twin-screw extruders, but sufficient for standard masterbatch applications.

- Design Parameters: Number and depth of channels, deflection angles, clearances.

- Material Type: Essential for polymers with difficult-to-disperse additives, high filler counts, or when you want to eliminate visual imperfections.

Design Parameters Relating to Efficiency:

• Number of Channels/Cavities/Pins: A higher number can increase mixing efficiency, but also pressure drop and heat generation.

• Channel/Cavity Depth: These influence the amount of material involved in mixing and shear rates. Deeper channels can reduce shear, while shallower channels increase it.

• Barrier Passageways/Geometry: The shape and geometry of the forced flow paths determine the effectiveness of distributive (doublings, rearrangements) and dispersive (localized shear) mixing.

• Clearances: The distance between the mixing element and the cylinder wall is critical. Smaller clearances increase shear and therefore dispersive mixing, but can also increase heat generation and pressure drop.

• Mixing Section Length: Longer sections allow for longer residence time and more opportunities for mixing.

• Helix Angle: For barrier mixers, the helix angle affects material transport and melting.

Conclusion:

Selecting the right mixer is an engineering process that requires a thorough understanding of the polymer, additives, mixing objectives, and operating conditions. Modern extrusion screws often combine different mixing sections (for example, a compression section with a barrier followed by a dispersive mixer) to optimize the process and achieve maximum product quality. Numerical simulation (FEM, CFD) plays an increasingly important role in optimizing mixer design, allowing us to predict the effects on flow, shear, and temperature prior to physical production.

Below is a comparison table with polymers, mixing objectives, recommended mixers, and operating notes.

| Polymer Type | Mixing Objective | Recommended Mixer | Operating Notes |

| Amorphous (PS, PVC, PMMA, ABS) | Color homogeneity, additive dispersion without degradation | Pineapple (Pin Mixer), Modified Maddock | Controlled shear, avoid excessive heating; be careful with heat-sensitive rigid PVC |

| Semicrystalline (PE, PP, PA) | Gradual melting and homogenization | Maillefer (barrier screw), Barrier Flight Mixer | Controlled melting, good distribution/dispersion combination; suitable for high throughput |

| Elastomers and high-viscosity polymers (EVA, TPU, thermoplastic rubber) | Moderate dispersiveness, additive homogenization | Pineapple, Maddock with optimized gap | Moderate shear to avoid thermal degradation |

| Pigmented compounds (masterbatches) | High dispersiveness for pigments and fillers | Maddock (CTM), Barrier Flight with reduced gap, Kneading Block (twin screw) | Pressure and heat control; Single-screw dispersive, limited but sufficient for standard masterbatches |

| Fiber-filled materials (glass, carbon) Avoid high-shear mixers to preserve fiber length | Distributive with minimal fiber breakage | Pineapple, Barrier Flight with controlled shear | Avoid high-shear mixers to preserve fiber length |

| Liquid or low-percentage additives | Uniform distribution on the micrometer scale | Pineapple, Maddock with deep channels | Promote distribution without overheating the polymer |